For those who are not engineers or designers by profession, understanding the 3D scanning process can be very difficult. Whether you are interested in implementing it into your company’s business model, or are considering learning to scan for yourself and opening a company, look no further than this page.

This page will endeavor to tell you what the purpose of scanning is, and how it can be adopted and used with great benefits. Scanning equipment is an amazing and innovative design feat that cannot be ignored and can seriously improve the efficiency and effectiveness of your business.

Here are the purposes of 3D scanning, and how they can benefit you, or your company.

Why Should I Find a 3D Scanning Service?

Why should I find a 3D scanning service? Well, you have found the right website to answer that question for you! These scanning services offer many benefits and can change the way that you do business. The process works by scanning the surface of a physical object and producing an online rendering, known as a ‘point cloud’. This ‘point cloud’ can be used to create a polygon surface, which is an exact model of the object you have scanned, on your computer.

The process is entirely non-contact, and the scans produce over a million points, which is a very high-quality and in-depth rendering, and far superior to other methods of scanning. Finding a good quality scanning service is imperative to the longevity and success of your company, and will help you to achieve your full potential and ditch more antiquated methods of scanning. If you do not want to learn how to scan objects for yourself, then finding service is the best option for you. You must shop comparatively and find the most effective and economically priced provider.

What is the Purpose of 3D Scanning?

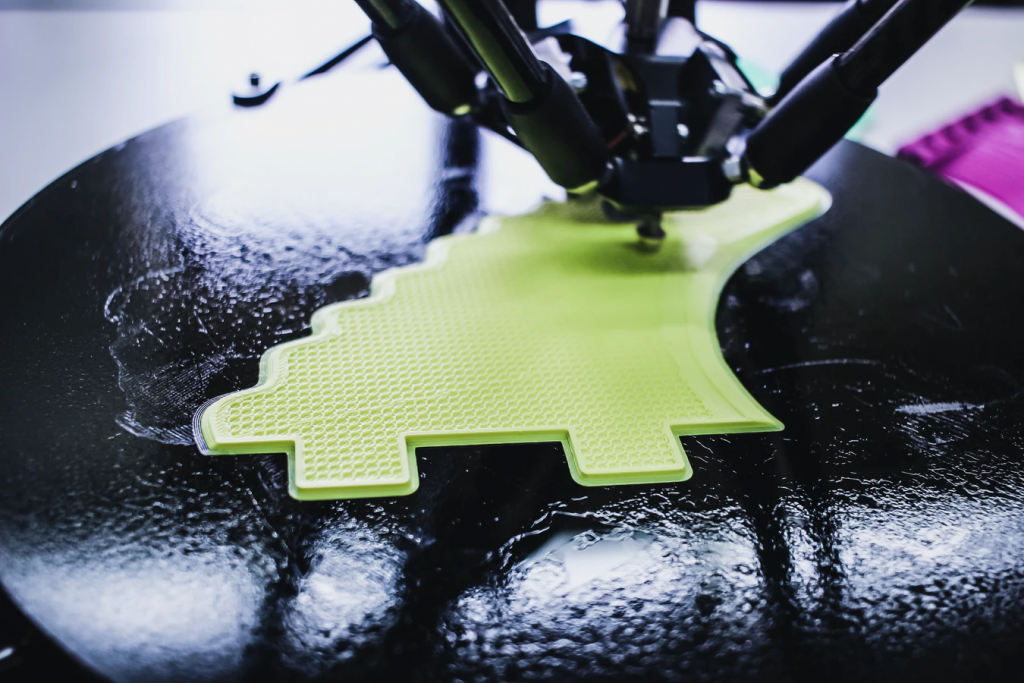

The purpose of 3D scanning is to create prototypes and aid you in designing products quicker and more effectively. When you are designing the prototype for a product, you can spend a long time attempting to perfect it; the use of 3D scanners, however, can reduce the amount of time that you spend doing this, and seriously improve your overall efficiency. These scanners are able to identify areas where an object has been changed so that you can come back to it later and continue altering and making adjustments.

How Efficient Are 3D Scanners?

3D scanners are very efficient. Their precision is like no other, and many people are beginning to realize this and are adopting the use of 3D scanners into their workshops. They allow you to check the quality and stability of a product before it is created in the real world and allows engineers to take measurements and thoroughly inspect potential products and identify any flaws digitally. This has reduced the amount of time spent correcting mistakes and improved the efficiency of many businesses from all echelons of industry. The quality of products designed by 3D scanners is unparalleled.

How Accurate Are 3D Scanners?

The accuracy of a 3D scanner, like the quality, is unparalleled and unrivaled. They allow you to inspect every single minute detail and potential flaw and identify anything that may become a problem in the future before your product becomes a physical object. This is a great way to cut costs and reduce spending. 3D scanners are so accurate, in fact, that museums around the world are using them to produce renderings of their artifacts and discover things that they had never noticed before. You can also use 3D scanners to make adjustments on older products that were produced before the software was available.

You can do this by creating a scan of an earlier object, and then compare the object with the new part you may be adding to it or something you may be removed. This reduces time spent measuring and means you do not have to do it physically on paper, as would once be the case. Many companies are using this as a method to remanufacture and improve earlier products, and it has achieved great success.

Comparative Design Models

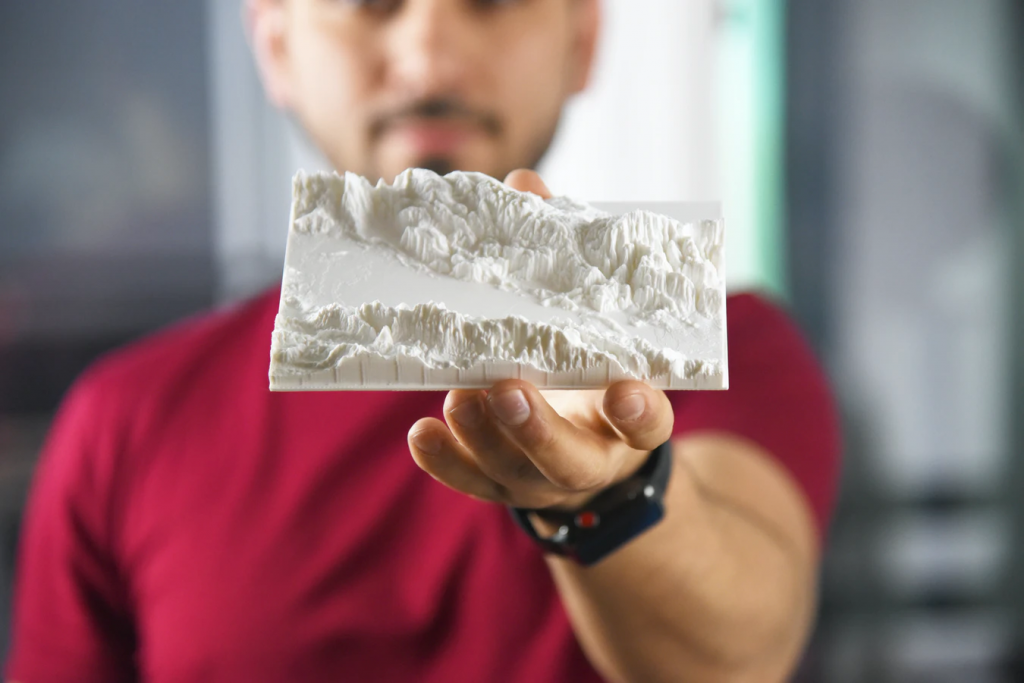

You can use 3D modeling equipment to compare your prototype with your finished product. This is a fantastic way to see if anything went wrong in the design process and to ensure that your product is how it is meant to be. There are many things that can go wrong when you are going from prototype to finished product, and this can identify what those may be.

Now you know about the accuracy, purpose, and benefits of 3D scanning services. If you need to employ the use of these services, then make sure you shop comparatively, and only do business with the professionals.