CNC machining stands for computer numeric controlled machining, which is one of the most famous and utilized manufacturing processes, first introduced between the 1940s and 1950s when the first numerical control machines emerged. The process itself includes multiple highly precise cutting instruments that remove material from the item — contingent upon the computer-aided drawing (CAD), which cutting-edge programming tools can entirely control.

In the last 80 years, this manufacturing process has helped millions of design teams and engineers successfully sketch and later produce their products with the opportunity of altering and making changes during the process. Moreover, the latest generation of CNC machining services uses such software that generates computer files with commands which enable it to run the machine for production.

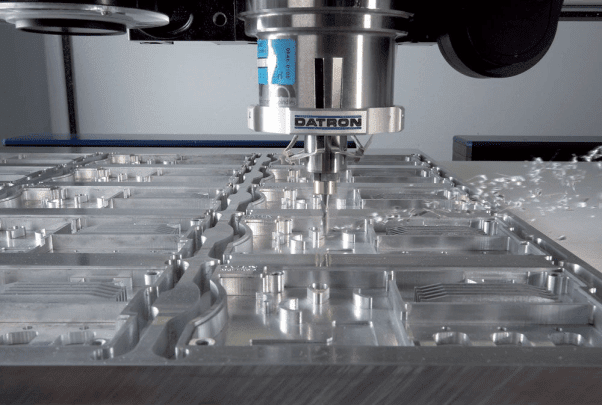

Commonly used CNC machining services include milling, cutting, drilling, and grinding among others. These basic CNC operations are commonly used together to produce single units or perform a particular CNC machining task. But, as you can see, CNC machining is really something else because each machine offers many functions and applications. Below, we’ll showcase the top four functions of CNC machining and how they work.

CNC Milling

To begin with, CNC milling is one of the most prominent features of CNC machining that utilizes specialized computer software to control the movement and speed of the spindle in order to create authentic and highly sophisticated pieces with high angled pressure. A CNC milling machine’s programming is typically based on either some unique language developed by a manufacturing team or G-code. Basic CNC mills consist of a three-axis system (x, y, and z), while most modern-day CNC machines can accommodate three additional axes.

The best thing about this feature of CNC machining is that it can work at multiple angles simultaneously, so producers can create various complex shapes that would be pretty difficult to achieve with other precision machines. In addition, CNC milling can produce pieces of different forms and even irregular shapes as well when needed.

CNC Turning

CNC Turning

CNC turning best applies to the production of specific parts. Most manufacturers utilize this CNC machining function to imprint materials, and it is referred to as turning because the workpiece spins as the machine works. As with CNC milling, CNC turning software is used to fully control the motion and speed of the machine to achieve precise and accurate results.

CNC turning allows designers to create round and tubular parts that can be used to further design prototypes and final products. CNC turning can be applied to multiple materials like copper, brass, nickel, stainless steel, aluminum, magnesium, and even plastics.

Electric Discharge Machining (EDM)

Electric discharge machining, or EDM, alternatively referred to as spark machining and die sinking, is a CNC machining process that molds the workpiece into particular shapes with the help of electrical sparks. With EDM, current discharges happen between two electrodes which remove sections of the given workpiece.

Once the leeway between the electrodes becomes smaller, the electric sphere becomes more and more intense and more potent than the dielectric, making it possible for a current to pass between the two electrodes. As a result, portions of the given workpiece are removed by each electrode. The two most famous subtypes of electric discharge machining include:

- Wide EDM which utilizes spark erosion to remove portions from an electronically conductive material;

- Sinker EDM uses an electrode and workpiece soaked in dielectric fluid for piece formulation.

Afterward, in a flushing procedure, debris from each completed workpiece is carried away by a liquid dielectric, which appears once the current between the two electrodes has stopped and is meant to eliminate any additional electric charges.

Water Jet Cutting

Water jet cutting is another feature of CNC machining used in cutting hard materials like metal and granite with high-pressure water applications. In some instances, the water could be mixed with sand or other potent abrasive substances. Large-scale companies often shape factory machine parts through water jet cutting.

Water jet cutting tools are utilized as a cooler alternative for materials that cannot bear the heat-intensive processes of other CNC machining techniques. Due to their cooler nature, sectors like mining and aerospace heavily rely on water jet cutting, where they use this technique for cutting and carving, among other functions. Businesses also utilize water jet cutters for making intricate cuts in material, as the lack of heat precludes any change in the material’s properties.

Final Thoughts

Above you can find the many functions of a single machine, and the best part is that there are many more. Nevertheless, all of the above can bring considerable benefits to your manufacturing business, including reducing labor costs, producing high-quality end products, providing quick solutions efficiently, and many more.